According to SPER Market Research, the Global Cement Waste Heat Recovery System Market is estimated to reach USD 33.92 billion by 2034 with a CAGR 7.94%.

Introduction and Overview

The report includes an in-depth analysis of the Global Cement Waste Heat Recovery System Market, including market size and trends, product mix, Applications, and supplier analysis.

The global Cement Waste Heat Recovery System Market was valued at USD 15.80 billion in 2024 and is expected to grow at a CAGR of over 7.94% from 2025 to 2034. Cement plants are highly energy-intensive, and waste heat recovery systems play a crucial role in reducing overall energy consumption. By capturing and reusing heat that would otherwise be lost, these systems help lower fuel expenses and improve profit margins. Increasingly strict government regulations aimed at reducing emissions are encouraging cement manufacturers to minimize their carbon footprints. Waste heat recovery solutions support compliance with environmental standards while enabling market growth. Additionally, tax benefits and government subsidies make these systems more affordable, easing investment in cleaner energy technologies. This results in lower greenhouse gas emissions and helps companies remain competitive. Continuous technological advancements have further improved system efficiency and reduced operating and maintenance costs. Modern, reliable, and cost-effective designs are attracting more cement producers and appealing to environmentally responsible customers.

By Voltage:

The application segments include pre-heating, electricity and steam generation, and others. The pre-heating segment dominates the application landscape, as it is widely adopted in cement plants to reuse exhaust heat for warming raw materials. Advanced multi-stage cyclone preheaters can recover high-temperature exhaust heat, significantly lowering kiln fuel demand and delivering fast payback periods. The electricity and steam generation segment is expected to grow steadily, as excess heat is used to run turbines for power and steam production. This reduces dependence on external energy sources, cuts operating costs, and improves overall energy efficiency in cement plants.

By Temperature:

Based on temperature, cement waste heat recovery systems are categorized into below 230 °C, 230 °C–650 °C, and above 650 °C ranges. Low-temperature heat is mainly reused for material drying or basic heating, offering simple, low-cost energy savings suitable for smaller plants. The 230 °C–650 °C range is widely used for electricity generation, as it provides a good balance between efficiency, investment cost, and operational ease. The above 650 °C segment dominates and continues to grow steadily, as high-temperature heat from clinker production enables large-scale power and steam generation, delivering maximum energy recovery and supporting stricter emission compliance in large cement plants.

Regional Insights:

The U.S. cement waste heat recovery system market showed highest growth between 2022 and 2024, driven by strict emission norms and the need to modernize aging cement infrastructure. In Europe, strong carbon-reduction targets and high energy prices are accelerating adoption, especially in countries such as Germany and France. Asia Pacific is witnessing rapid expansion due to rising cement production, increasing energy costs, and supportive government policies in China and India. In the Middle East & Africa, large infrastructure projects and efforts to reduce energy imports are boosting demand. Latin America is growing gradually, with higher energy prices, environmental regulations, and foreign investments supporting future market expansion.

Market Competitive Landscape:

The Cement Waste Heat Recovery System Market is highly consolidated. Some of the market key players are AURA, Bosch Industriekessel GmbH, Climeon, Cochran, CTP TEAM S.R.L, Forbes Marshall, IHI Corporation, John Wood Group PLC, Kawasaki Heavy Industries, Ltd., MITSUBISHI HEAVY INDUSTRIES, LTD., Promec Engineering, Siemens Energy

Recent Developments:

• MITSUBISHI HEAVY INDUSTRIES, LTD., a Japan-based company, reported USD 31.2 billion in revenue in 2024 and offers advanced waste heat recovery solutions for cement plants using steam turbine and Kalina Cycle technologies.

• Thermax Limited, based in India, recorded revenues of USD 1.1 billion in 2024. The company specializes in energy and environmental solutions and provides ORC-based waste heat recovery systems for cement plants, mainly across the Asia-Pacific region.

Scope of the report:

Report Metric Details

Market size available for the years 2021-2034

Base year considered 2024

Forecast Period 2025-2034

Segments Covered By Application, By Temperature

Regions Covered North America, Latin America, Asia-Pacific, Europe, and Middle East & Africa

Companies Covered AURA, Bosch Industriekessel GmbH, Climeon, Cochran, CTP TEAM S.R.L, Forbes Marshall, IHI Corporation, John Wood Group PLC, Kawasaki Heavy Industries, Ltd., MITSUBISHI HEAVY INDUSTRIES, LTD., Promec Engineering, Siemens Energy

Key Topics Covered in the Report

• Global Cement Waste Heat Recovery System Market Size (FY’2021-FY’2034)

• Overview of Global Cement Waste Heat Recovery System Market

• Segmentation of Global Cement Waste Heat Recovery System Market By Application (Pre-heating, Electricity & steam generation, other)

• Segmentation of Global Cement Waste Heat Recovery System Market By Temperature (230°C, 230°C - 650 °C, > 650 °C)

• Statistical Snap of Global Cement Waste Heat Recovery System Market

• Expansion Analysis of Global Cement Waste Heat Recovery System Market

• Problems and Obstacles in Global Cement Waste Heat Recovery System Market

• Competitive Landscape in the Global Cement Waste Heat Recovery System Market

• Details on Current Investment in Global Cement Waste Heat Recovery System Market

• Competitive Analysis of Global Cement Waste Heat Recovery System Market

• Prominent Players in the Global Cement Waste Heat Recovery System Market

• SWOT Analysis of Global Cement Waste Heat Recovery System Market

• Global Cement Waste Heat Recovery System Market Future Outlook and Projections (FY’2025-FY’2034)

• Recommendations from Analyst

Global Cement Waste Heat Recovery System Market Size- By Application, By Temperature- Regional Outlook, Competitive Strategies and Segment Forecast to 2034

1. Introduction

1.1. Scope of the report

1.2. Market segment analysis

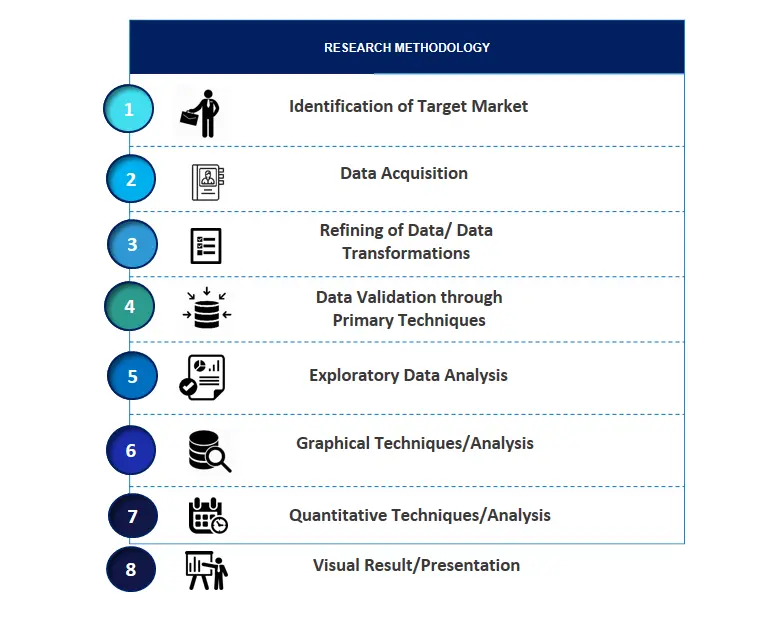

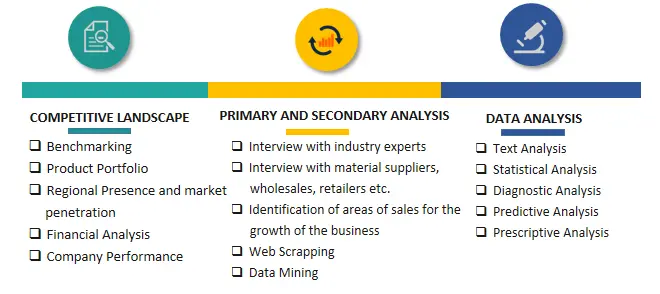

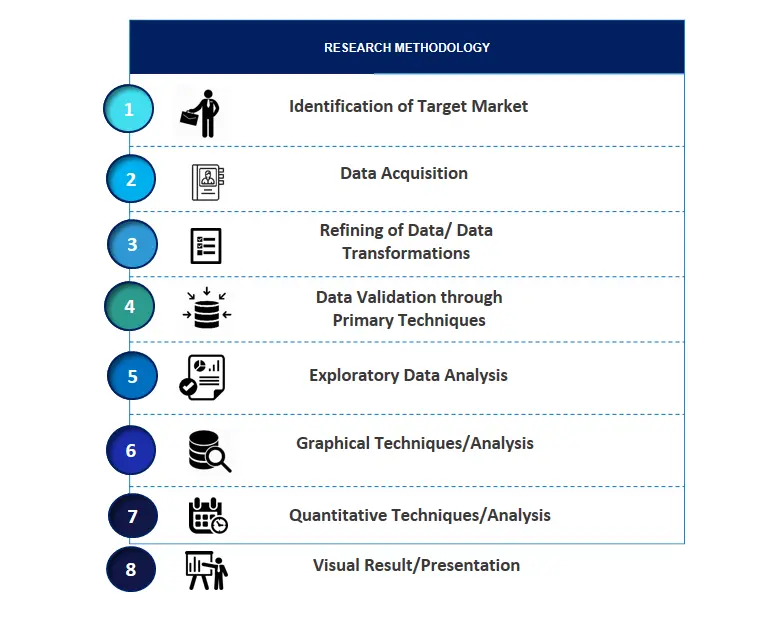

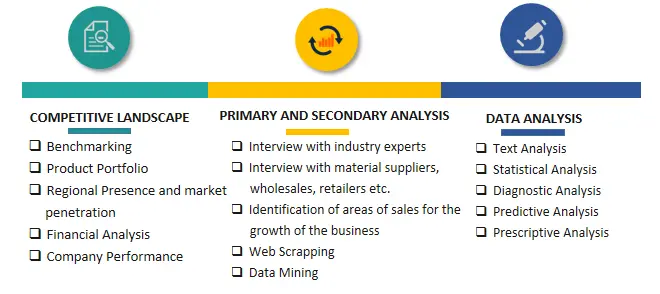

2. Research Methodology

2.1. Research data source

2.1.1. Secondary Data

2.1.2. Primary Data

2.1.3. SPER’s internal database

2.1.4. Premium insight from KOL’s

2.2. Market size estimation

2.2.1. Top-down and Bottom-up approach

2.3. Data triangulation

3. Executive Summary

4. Market Dynamics

4.1. Driver, Restraint, Opportunity and Challenges analysis

4.1.1. Drivers

4.1.2. Restraints

4.1.3. Opportunities

4.1.4. Challenges

5. Market variable and outlook

5.1. SWOT Analysis

5.1.1. Strengths

5.1.2. Weaknesses

5.1.3. Opportunities

5.1.4. Threats

5.2. PESTEL Analysis

5.2.1. Political Landscape

5.2.2. Economic Landscape

5.2.3. Social Landscape

5.2.4. Technological Landscape

5.2.5. Environmental Landscape

5.2.6. Legal Landscape

5.3. PORTER’s Five Forces

5.3.1. Bargaining power of suppliers

5.3.2. Bargaining power of buyers

5.3.3. Threat of Substitute

5.3.4. Threat of new entrant

5.3.5. Competitive rivalry

5.4. Heat Map Analysis

6. Competitive Landscape

6.1. Global Cement Waste Heat Recovery System Market Manufacturing Base Distribution, Sales Area, Product Type

6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in Global Cement Waste Heat Recovery System Market

7. Global Cement Waste Heat Recovery System Market, By Application, (USD Million) 2021-2034

7.1. Pre-heating

7.2. Electricity & steam generation

7.2.1. Steam rankine cycle

7.2.2. Organic rankine cycle

7.2.3. Kalina cycle

7.3. Other

8. Global Cement Waste Heat Recovery System Market, By Temperature, (USD Million) 2021-2034

8.1. 230°C

8.2. 230°C - 650 °C

8.3. > 650 °C

9. Global Cement Waste Heat Recovery System Market, (USD Million) 2021-2034

9.1. Global Cement Waste Heat Recovery System Market Size and Market Share

10. Global Cement Waste Heat Recovery System Market, By Region, 2021-2034 (USD Million)

10.1. Asia-Pacific

10.1.1. Australia

10.1.2. China

10.1.3. India

10.1.4. Japan

10.1.5. South Korea

10.1.6. Rest of Asia-Pacific

10.2. Europe

10.2.1. France

10.2.2. Germany

10.2.3. Italy

10.2.4. Spain

10.2.5. United Kingdom

10.2.6. Rest of Europe

10.3. Middle East and Africa

10.3.1. Kingdom of Saudi Arabia

10.3.2. United Arab Emirates

10.3.3. Qatar

10.3.4. South Africa

10.3.5. Egypt

10.3.6. Morocco

10.3.7. Nigeria

10.3.8. Rest of Middle-East and Africa

10.4. North America

10.4.1. Canada

10.4.2. Mexico

10.4.3. United States

10.5. Latin America

10.5.1. Argentina

10.5.2. Brazil

10.5.3. Rest of Latin America

11. Company Profile

11.1. AURA

11.1.1. Company details

11.1.2. Financial outlook

11.1.3. Product summary

11.1.4. Recent developments

11.2. Bosch Industriekessel GmbH

11.2.1. Company details

11.2.2. Financial outlook

11.2.3. Product summary

11.2.4. Recent developments

11.3. Climeon

11.3.1. Company details

11.3.2. Financial outlook

11.3.3. Product summary

11.3.4. Recent developments

11.4. Cochran

11.4.1. Company details

11.4.2. Financial outlook

11.4.3. Product summary

11.4.4. Recent developments

11.5. CTP TEAM S.R.L

11.5.1. Company details

11.5.2. Financial outlook

11.5.3. Product summary

11.5.4. Recent developments

11.6. Forbes Marshall

11.6.1. Company details

11.6.2. Financial outlook

11.6.3. Product summary

11.6.4. Recent developments

11.7. IHI Corporation

11.7.1. Company details

11.7.2. Financial outlook

11.7.3. Product summary

11.7.4. Recent developments

11.8. John Wood Group PLC

11.8.1. Company details

11.8.2. Financial outlook

11.8.3. Product summary

11.8.4. Recent developments

11.9. Kawasaki Heavy Industries, Ltd.

11.9.1. Company details

11.9.2. Financial outlook

11.9.3. Product summary

11.9.4. Recent developments

11.10. MITSUBISHI HEAVY INDUSTRIES, LTD.

11.10.1. Company details

11.10.2. Financial outlook

11.10.3. Product summary

11.10.4. Recent developments

11.11. Promec Engineering

11.11.1. Company details

11.11.2. Financial outlook

11.11.3. Product summary

11.11.4. Recent developments

11.12. Siemens Energy

11.12.1. Company details

11.12.2. Financial outlook

11.12.3. Product summary

11.12.4. Recent developments

11.13. Others

12. Conclusion

13. List of Abbreviations

14. Reference Links

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.