United States Automotive Parts Die Casting Market Trends, Share, Size, Demand and Future Outlook

United States Automotive Parts Die Casting Market Growth, Size, Trends Analysis- By Process, By Raw Material- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

| Published: Oct-2024 | Report ID: AMIN24226 | Pages: 1 - 107 | Formats*: |

| Category : Automotive & Transportation | |||

- In November 2023, Tooling & Equipment International, a Livonia, Michigan-based company that develops and produces casting moulds and tooling, prototypes, and low-volume production castings, was acquired by General Motors Corp. In order to produce automobile castings in large quantities, including cylinder heads, cylinder blocks, drivelines, chassis, and suspension castings, General Motors (GM) will leverage Tooling & Equipment International's expertise in mould and core box design.

- In November 2023, Linamar announced that it will use its new gigacasting facility in Ontario to sell its goods to the EV industry. The gigacasting plant owned and run by a North American parts manufacturer will be the first one when it opens at Linamar.

| Report Metric | Details |

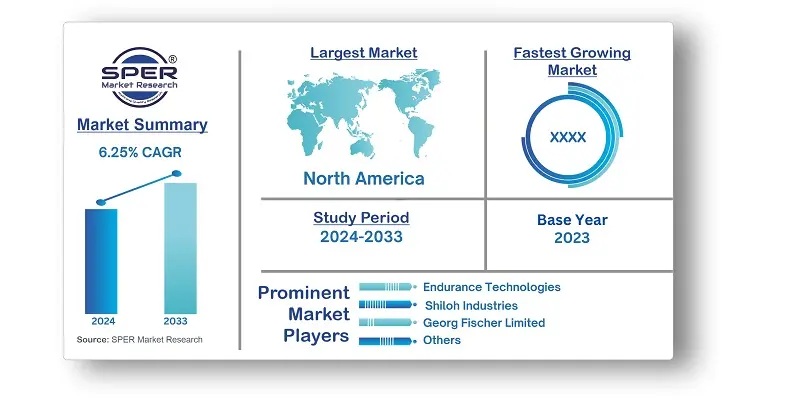

| Market size available for years | 2020-2033 |

| Base year considered | 2023 |

| Forecast period | 2024-2033 |

| Segments covered | By Process, By Raw Material |

| Regions covered | Northeast, South, Midwest, West |

| Companies Covered | Nemak, Endurance Technologies, Shiloh Industries, Georg Fischer Limited, Bocar Group, Rheinmetall AG, Rockman Industries, Ryobi Die Casting LTD. |

- Automobile Manufacturers (OEMs)

- Automotive Parts Suppliers

- Electric Vehicle Manufacturers

- Tier-1 and Tier-2 Suppliers

- Lightweight Vehicle Manufacturers

- Automotive Aftermarket Suppliers

- Construction and Heavy Equipment Manufacturers

- Automotive R&D and Engineering Firms

- Aluminum and Magnesium Suppliers

| By Process: | |

| By Raw Material: |

- United States Automotive Parts Die Casting Market Size (FY’2024-FY’2033)

- Overview of United States Automotive Parts Die Casting Market

- Segmentation of United States Automotive Parts Die Casting Market By Process (Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, Others)

- Segmentation of United States Automotive Parts Die Casting Market By Raw Material (Aluminium, Magnesium, Zinc)

- Statistical Snap of United States Automotive Parts Die Casting Market

- Expansion Analysis of United States Automotive Parts Die Casting Market

- Problems and Obstacles in United States Automotive Parts Die Casting Market

- Competitive Landscape in the United States Automotive Parts Die Casting Market

- Impact of COVID-19 and Demonetization on United States Automotive Parts Die Casting Market

- Details on Current Investment in United States Automotive Parts Die Casting Market

- Competitive Analysis of United States Automotive Parts Die Casting Market

- Prominent Players in the United States Automotive Parts Die Casting Market

- SWOT Analysis of United States Automotive Parts Die Casting Market

- United States Automotive Parts Die Casting Market Future Outlook and Projections (FY’2024-FY’2033)

- Recommendations from Analyst

1.1. Scope of the report1.2. Market segment analysis

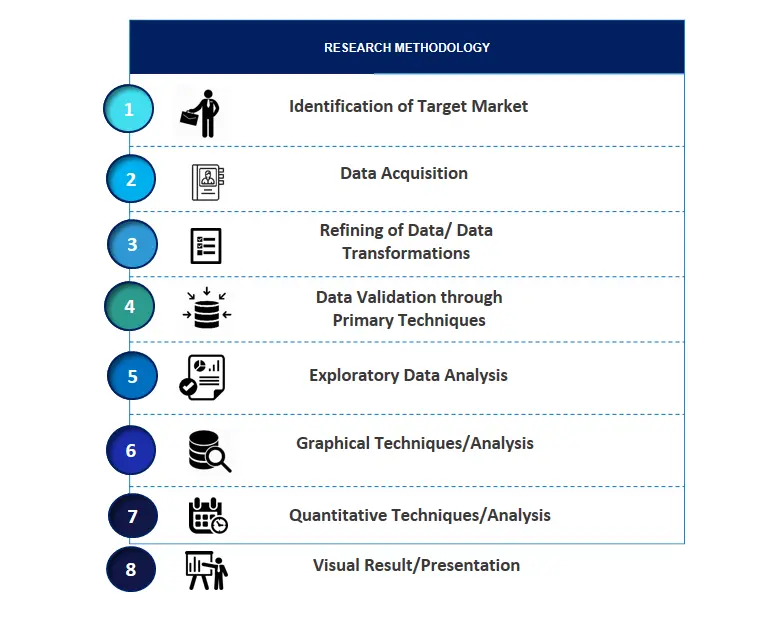

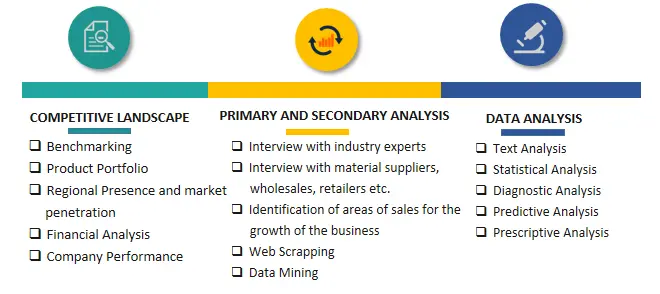

2.1. Research data source2.1.1. Secondary Data2.1.2. Primary Data2.1.3. SPER’s internal database2.1.4. Premium insight from KOL’s2.2. Market size estimation2.2.1. Top-down and Bottom-up approach2.3. Data triangulation

4.1. Driver, Restraint, Opportunity and Challenges analysis4.1.1. Drivers4.1.2. Restraints4.1.3. Opportunities4.1.4. Challenges4.2. COVID-19 Impacts of the United States Automotive Parts Die Casting Market.

5.1. SWOT Analysis5.1.1. Strengths5.1.2. Weaknesses5.1.3. Opportunities5.1.4. Threats5.2. PESTEL Analysis5.2.1. Political Landscape5.2.2. Economic Landscape5.2.3. Social Landscape5.2.4. Technological Landscape5.2.5. Environmental Landscape5.2.6. Legal Landscape5.3. PORTER’s Five Forces5.3.1. Bargaining power of suppliers5.3.2. Bargaining power of buyers5.3.3. Threat of Substitute5.3.4. Threat of new entrant5.3.5. Competitive rivalry5.4. Heat Map Analysis

6.1. United States Automotive Parts Die Casting Market Manufacturing Base Distribution, Sales Area, Product Type6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in United States Automotive Parts Die Casting Market

7.1. United States Automotive Parts Die Casting Market Size, Share and Forecast, By Process, 2020-20267.2. United States Automotive Parts Die Casting Market Size, Share and Forecast, By Process, 2027-20337.3. Pressure Die Casting7.4. Vacuum Die Casting7.5. Squeeze Die Casting7.6. Others

8.1. United States Automotive Parts Die Casting Market Size, Share and Forecast, By Raw Material, 2020-20268.2. United States Automotive Parts Die Casting Market Size, Share and Forecast, By Raw Material, 2027-20338.3. Aluminium8.4. Magnesium8.5. Zinc

9.1. United States Automotive Parts Die Casting Market Size and Market Share

10.1. United States Automotive Parts Die Casting Market Size and Market Share By Region (2020-2026)10.2. United States Automotive Parts Die Casting Market Size and Market Share By Region (2027-2033)10.3. Northeast10.4. South10.5. Midwest10.6. West

11.1. Nemak11.1.1. Company details11.1.2. Financial outlook11.1.3. Product summary11.1.4. Recent developments11.2. Endurance Technologies11.2.1. Company details11.2.2. Financial outlook11.2.3. Product summary11.2.4. Recent developments11.3. Shiloh Industries11.3.1. Company details11.3.2. Financial outlook11.3.3. Product summary11.3.4. Recent developments11.4. Georg Fischer Limited11.4.1. Company details11.4.2. Financial outlook11.4.3. Product summary11.4.4. Recent developments11.5. Bocar Group11.5.1. Company details11.5.2. Financial outlook11.5.3. Product summary11.5.4. Recent developments11.6. Rheinmetall AG11.6.1. Company details11.6.2. Financial outlook11.6.3. Product summary11.6.4. Recent developments11.7. Rockman Industries11.7.1. Company details11.7.2. Financial outlook11.7.3. Product summary11.7.4. Recent developments11.8. Ryobi Die Casting LTD11.8.1. Company details11.8.2. Financial outlook11.8.3. Product summary11.8.4. Recent developments11.9. Others

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.

Frequently Asked Questions About This Report

PLACE AN ORDER

Year End Discount

Sample Report

Pre-Purchase Inquiry

NEED CUSTOMIZATION?

Request CustomizationCALL OR EMAIL US

100% Secure Payment

Related Reports

Our Global Clients

Our data-driven insights have influenced the strategy of 200+ reputed companies across the globe.