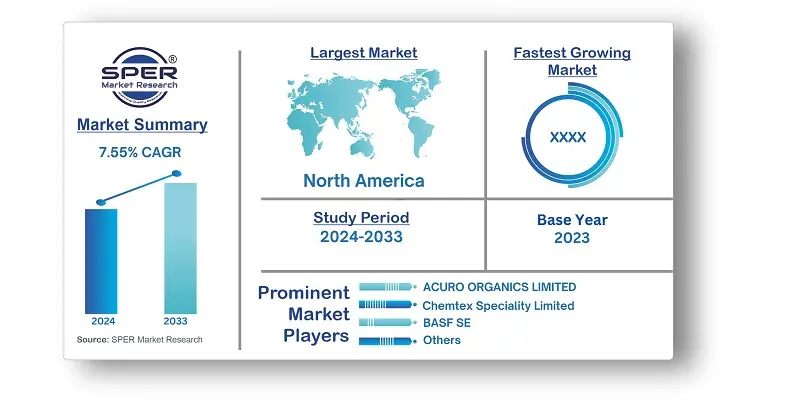

Acrylic Processing Aid Market Growth, Size, Trends, Demand, Share, Revenue and Future Outlook

Acrylic Processing Aid Market Size- By Polymer Type, By Fabrication Process, By Application, By End-Use Industry- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

| Published: May-2024 | Report ID: CHEM2445 | Pages: 1 - 210 | Formats*: |

| Category : Chemical & Materials | |||

- PLASTISTRENGTH® 562 NA, a new process aid from Arkema, will be available in July 2020. Its goal is to help PVC converters better balance formulation costs with processing performance. Increased melt power, efficient processing, and continuous PVC fusion and filler integration are all provided by this innovative technique for both rigid and semi-rigid extruded or calendared PVC products.

- October 2022: Industry 4.0 technology integration is one industrial advancement in the acrylic processing aid sector. Using automation, the Internet of Things, and data analytics, manufacturers are using smart manufacturing processes more and more. This connection guarantees constant product quality, lowers downtime, and increases production efficiency. Optimal manufacturing in the acrylic processing aid industry is facilitated by predictive maintenance, data-driven insights, and real-time production process monitoring. By using Industry 4.0, the acrylic processing aid manufacturing landscape becomes more flexible and simplified, while also improving operational efficiency and positioning the industry to meet the changing demands of a technologically evolved market.

Market Opportunities and Challenges

Market Opportunities and Challenges

| Report Metric | Details |

| Market size available for years | 2020-2033 |

| Base year considered | 2023 |

| Forecast period | 2024-2033 |

| Segments covered | By Polymer Type, By Fabrication Process, By Application, By End-Use Industry |

| Regions covered | North America, Asia-Pacific, Latin America, Middle East & Africa and Europe |

| Companies Covered | ACURO ORGANICS LIMITED, Maxwell Additives Pvt Ltd, Chemtex Speciality Limited, Polysciences, Inc, PROTEX INTERNATIONAL, Ashland, Arkema, BASF SE, Kemira, The Lubrizol Corporation, NIPPON SHOKUBAI CO LTD, Evonik Industries AG, Dow, Henan Qingshuiyuan Technology CO, Ltd, Aurora Fine Chemicals, Zouping Dongfang Chemical Co, Ltd. |

- Manufacturers

- Distributors

- Suppliers

- Logistics organizations

- Government bodies

| By Polymer Type: |

|

| By Fabrication Process: |

|

| By Application: |

|

| By End-Use Industry: |

|

- Global Acrylic Processing Aid Market Size (FY’2024-FY’2033)

- Overview of Global Acrylic Processing Aid Market

- Segmentation of Global Acrylic Processing Aid Market By Polymer Type (Polyvinyl Chloride, Others)

- Segmentation of Global Acrylic Processing Aid Market By Fabrication Process (Extrusion, Injection Molding, Others)

- Segmentation of Global Acrylic Processing Aid Market By Application (Pipes, and Fitting, Door and Window, Packaging and Films, Furniture, Footwear, Others)

- Segmentation of Global Acrylic Processing Aid Market By End-Use Industry (Building and Construction, Packaging, Consumer Good, Automotive, Others)

- Statistical Snap of Global Acrylic Processing Aid Market

- Expansion Analysis of Global Acrylic Processing Aid Market

- Problems and Obstacles in Global Acrylic Processing Aid Market

- Competitive Landscape in the Global Acrylic Processing Aid Market

- Impact of COVID-19 and Demonetization on Global Acrylic Processing Aid Market

- Details on Current Investment in Global Acrylic Processing Aid Market

- Competitive Analysis of Global Acrylic Processing Aid Market

- Prominent Players in the Global Acrylic Processing Aid Market

- SWOT Analysis of Global Acrylic Processing Aid Market

- Global Acrylic Processing Aid Market Future Outlook and Projections (FY’2024-FY’2033)

- Recommendations from Analyst

1.1. Scope of the report1.2. Market segment analysis

2.1. Research data source2.1.1. Secondary Data2.1.2. Primary Data2.1.3. SPER’s internal database2.1.4. Premium insight from KOL’s2.2. Market size estimation2.2.1. Top-down and Bottom-up approach2.3. Data triangulation

4.1. Driver, Restraint, Opportunity and Challenges analysis4.1.1. Drivers4.1.2. Restraints4.1.3. Opportunities4.1.4. Challenges4.2. COVID-19 Impacts of the Global Acrylic Processing Aid Market.

5.1. SWOT Analysis5.1.1. Strengths5.1.2. Weaknesses5.1.3. Opportunities5.1.4. Threats5.2. PESTEL Analysis5.2.1. Political Landscape5.2.2. Economic Landscape5.2.3. Social Landscape5.2.4. Technological Landscape5.2.5. Environmental Landscape5.2.6. Legal Landscape5.3. PORTER’s Five Forces5.3.1. Bargaining power of suppliers5.3.2. Bargaining power of buyers5.3.3. Threat of Substitute5.3.4. Threat of new entrant5.3.5. Competitive rivalry5.4. Heat Map Analysis

6.1. Global Acrylic Processing Aid Market Manufacturing Base Distribution, Sales Area, Product Type6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in Global Acrylic Processing Aid Market

7.1. Global Acrylic Processing Aid Market Size, Share and Forecast, By Polymer Type, 2020-20267.2. Global Acrylic Processing Aid Market Size, Share and Forecast, By Polymer Type, 2027-20337.3. Polyvinyl Chloride7.4. Others

8.1. Global Acrylic Processing Aid Market Size, Share and Forecast, By Fabrication Process, 2020-20268.2. Global Acrylic Processing Aid Market Size, Share and Forecast, By Fabrication Process, 2027-20338.3. Extrusion8.4. Injection Molding8.5. Others

9.1. Global Acrylic Processing Aid Market Size, Share and Forecast, By Application, 2020-20269.2. Global Acrylic Processing Aid Market Size, Share and Forecast, By Application, 2027-20339.3. Pipes and Fitting9.4. Door and Window9.5. Packaging and Films9.6. Furniture9.7. Footwear9.8. Others

10.1. Global Acrylic Processing Aid Market Size, Share and Forecast, By End-Use Industry, 2020-202610.2. Global Acrylic Processing Aid Market Size, Share and Forecast, By End-Use Industry, 2027-203310.3. Building and Construction10.4. Packaging10.5. Consumer Goods10.6. Automotive10.7. Others

11.1. Global Acrylic Processing Aid Market Size and Market Share

12.1. Global Acrylic Processing Aid Market Size and Market Share By Region (2020-2026)12.2. Global Acrylic Processing Aid Market Size and Market Share By Region (2027-2033)12.3. Asia-Pacific12.3.1. Australia12.3.2. China12.3.3. India12.3.4. Japan12.3.5. South Korea12.3.6. Rest of Asia-Pacific12.4. Europe12.4.1. France12.4.2. Germany12.4.3. Italy12.4.4. Spain12.4.5. United Kingdom12.4.6. Rest of Europe12.5. Middle East and Africa12.5.1. Kingdom of Saudi Arabia12.5.2. United Arab Emirates12.5.3. Qatar12.5.4. South Africa12.5.5. Egypt12.5.6. Morocco12.5.7. Nigeria12.5.8. Rest of Middle-East and Africa12.6. North America12.6.1. Canada12.6.2. Mexico12.6.3. United States12.7. Latin America12.7.1. Argentina12.7.2. Brazil12.7.3. Rest of Latin America

13.1. Ashland13.1.1. Company details13.1.2. Financial outlook13.1.3. Product summary13.1.4. Recent developments13.2. Arkema13.2.1. Company details13.2.2. Financial outlook13.2.3. Product summary13.2.4. Recent developments13.3. BASF SE13.3.1. Company details13.3.2. Financial outlook13.3.3. Product summary13.3.4. Recent developments13.4. Kemira13.4.1. Company details13.4.2. Financial outlook13.4.3. Product summary13.4.4. Recent developments13.5. The Lubrizol Corporation13.5.1. Company details13.5.2. Financial outlook13.5.3. Product summary13.5.4. Recent developments13.6. NIPPON SHOKUBAI CO. LTD13.6.1. Company details13.6.2. Financial outlook13.6.3. Product summary13.6.4. Recent developments13.7. Dow13.7.1. Company details13.7.2. Financial outlook13.7.3. Product summary13.7.4. Recent developments13.8. Henan Qingshuiyuan Technology CO., Ltd.13.8.1. Company details13.8.2. Financial outlook13.8.3. Product summary13.8.4. Recent developments13.9. Aurora Fine Chemicals13.9.1. Company details13.9.2. Financial outlook13.9.3. Product summary13.9.4. Recent developments13.10. Zouping Dongfang Chemical Co., Ltd.13.10.1. Company details13.10.2. Financial outlook13.10.3. Product summary13.10.4. Recent developments13.11. ACURO ORGANICS LIMITED13.11.1. Company details13.11.2. Financial outlook13.11.3. Product summary13.11.4. Recent developments13.12. Maxwell Additives Pvt. Ltd13.12.1. Company details13.12.2. Financial outlook13.12.3. Product summary13.12.4. Recent developments13.13. Chemtex Speciality Limited13.13.1. Company details13.13.2. Financial outlook13.13.3. Product summary13.13.4. Recent developments13.14. Polysciences, Inc.13.14.1. Company details13.14.2. Financial outlook13.14.3. Product summary13.14.4. Recent developments13.15. PROTEX INTERNATIONAL13.15.1. Company details13.15.2. Financial outlook13.15.3. Product summary13.15.4. Recent developments13.16. Evonik Industries AG13.16.1. Company details13.16.2. Financial outlook13.16.3. Product summary13.16.4. Recent developments13.17. Others

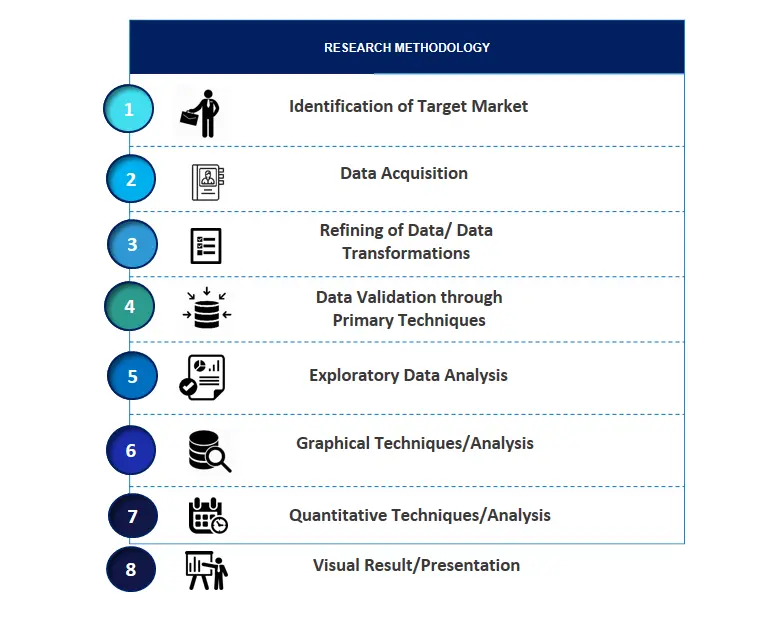

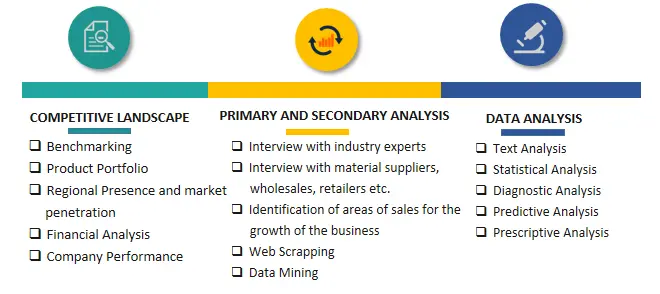

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.

Frequently Asked Questions About This Report

PLACE AN ORDER

Year End Discount

Sample Report

Pre-Purchase Inquiry

NEED CUSTOMIZATION?

Request CustomizationCALL OR EMAIL US

100% Secure Payment

Related Reports

Our Global Clients

Our data-driven insights have influenced the strategy of 200+ reputed companies across the globe.