Global Pharmaceutical Filtration Market Insights, Size and Growth Forecast To 2030

Pharmaceutical Filtration Market Size, Share & Trends Analysis By Product, By Systems, By Technique, By Application, By Scale of Operation, Regional Outlook, Competitive Strategies and Segment Forecasts to 2030

| Published: Jun-2022 | Report ID: BIOT2228 | Pages: 1 - 208 | Formats*: |

| Category : Biotechnology | |||

| Report Metric | Details |

| Market size available for years | 2019-2030 |

| Base year considered | 2021 |

| Forecast period | 2022-2030 |

| Segments covered | By Product, By Systems, By Technique, By Application, By Scale of Operation |

| Geographies covered | North America, Europe, Asia Pacific, Latin America, Middle East, Africa |

| Companies Covered | Alfa Laval Corporate AB, Amazon Filters LTD, Cantel Medical Corp., Cole-Parmer Instrument Company LCC., Corning Incorporated., Donaldson Company, Inc., Danaher Corporation, Eaton Corporation PLC., Ertelalsop, Filtrox AG., Freudenberg Filtration Technologies SE & CO.KG, Graver Technologies, LLC., Kasag Swiss AG., Membrane Solutions., Merck KGAA. , MMS AG., Mann + Hummel International GMBH & CO. KG, Meissner Filtration Products, INC., Parker + Hannifin Corporation , Porvair PLC. , Repligen Corporation., Saint-Gobain Performance Plastics. , Sartorius AG. , 3M Company. |

1.1. Scope of the report1.2. Market segment analysis

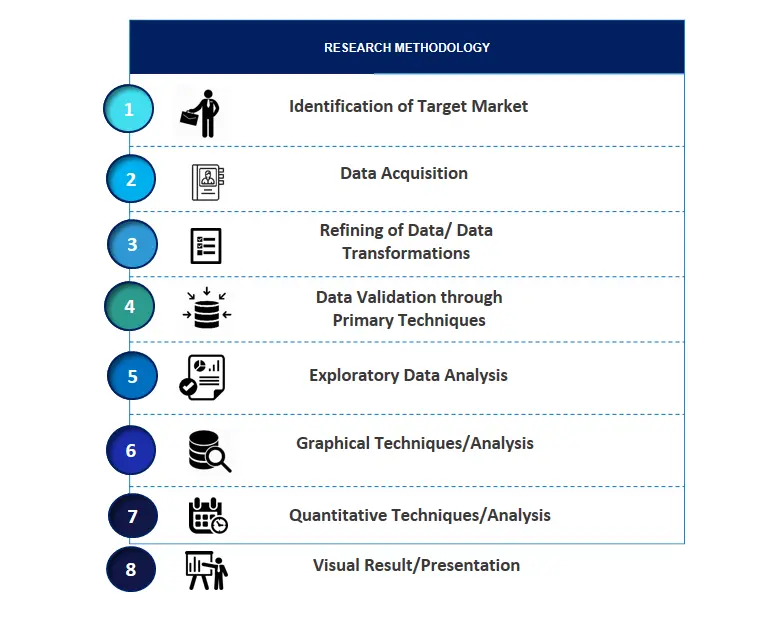

2.1 Research data source

2.1.1 Secondary data2.1.2 Primary data2.1.3 SPER’s internal database2.1.4 Premium insight from KOL’s

2.2 Market size estimation

2.2.1 Top-down and Bottom-up approach

2.3 Data triangulation

4.1. Driver, Restraint, Opportunity and Challenges analysis

4.1.1 Drivers4.1.2 Restraints4.1.3 Opportunities4.1.4 Challenges

4.2. COVID-19 Impacts of the Pharmaceutical Filtration Market

5.1. SWOT analysis

5.1.1 Strengths5.1.2 Weaknesses5.1.3 Opportunities5.1.4 Threats

5.2. PESTEL analysis

5.2.1 Political landscape5.2.2 Economic landscape5.2.3 Social landscape5.2.4 Technological landscape5.2.5 Environmental landscape5.2.6 Legal landscape

5.3. PORTER’S five forces analysis

5.3.1 Bargaining power of suppliers5.3.2 Bargaining power of Buyers5.3.3 Threat of Substitute5.3.4 Threat of new entrant5.3.5 Competitive rivalry

5.4. Heat map analysis

6.1 Introduction6.2. Filter

6.2.1 Membrane Filters6.2.1.1.Polyethersulfone (PES)6.2.1.2 Polyvinylidene difluoride (PVDF)6.2.1.3 Nylon6.2.1.4 Polytetrafluroethylene (PTFE)6.2.1.5. Mixed cellulose ester & cellulose acetate (MCE & CA)6.2.1.6 Polycarbonated Track-Etched (PCTE)6.2.1.7 Other materials

6.2.2 Depth Filters6.2.2.1 Diatomaceous earth6.2.2.1.1. Diatomaceous Earth to be used in-depth filters in biotechnology industry for cell clarification6.2.2.2 Cellulose6.2.2.2.1. Cost-effectiveness of cellulose-based depth filter to drive market growth.6.2.2.3 Activated Carbon6.2.2.3.1. Reliable and economic activated carbon filters to be used in traditional pharmaceutical manufacturing operations.6.2.2.4 Perlite6.2.2.4.1. Perlite is lower in density to provide more purity than diatomaceous earth6.2.2.5 Other Depth Filter Media

6.2.3 Other Filters

6.3 Systems

6.3.1 Single-use systems6.3.1.1. Reduced need for product validation and minimized cross-contamination risk to boost single-use systems adoption6.3.2 Reusable systems6.3.2.1. Reusable systems to be used for large-scale manufacturing

6.4 Other Filtration Products

6.4.1 Filtration Assemblies6.4.2 Filter Holder6.4.2.1. Filter holders to provide structural support to membrane filters6.4.3 Filtration Accessories6.4.3.1. Increase in pharmaceutical filtration products adoption to support associated accessories used

7.1. Introduction7.2. Microfiltration

7.2.1. Increased adoption of Microfiltration Technique and cost-effective nature to propel Market growth

7.3. Ultrafiltration

7.3.1. Adoption of Fine Filtration Technique to drive Market growth

7.4. Nanofiltration

7.4.1. High energy Consumption to hider Market growth

7.5. Other Techniques

7.5.1. High Purity water requirement during Biopharmaceutical manufacturing to increase Market growth

8.1. Introduction8.2. Sterile Filtration

8.2.1. Increased manufacturing of Bilogics drugs to drive sterile filtration demand.

8.3. Non sterile Filtration

8.3.1. Growth of R&D activities to promote Market growth

9.1 Introduction9.2 Final Product Processing

9.2.1 Active Pharmaceutical Ingredients (API) Filtration9.2.1.1. Continuous filtration of API filtration to increase market growth9.2.2 Protein Purification9.2.2.1. Recent advancement in protein therapeutic drugs to propel market growth9.2.3 Vaccine and Antibody Processing9.2.3.1. Rise in COVID-19 pandemic and other viral diseases to drive vaccine and antibody processing market9.2.4 Formulation and Filling Solutions9.2.4.1. Demand for aseptic filling and bioburden reduction to increase market growth9.2.5 Viral Clearance9.2.5.1. Growth in therapeutic monoclonal antibodies to increase market growth

9.3 Raw Material Filtration

9.3.1 Media Buffer Filtration9.3.1.1. Growth in manufacturing of biopharmaceuticals to improve market growth9.3.2 Prefiltration9.3.2.1. Membrane fouling to increase market growth for prefilters9.3.3 Bioburden Testing9.3.3.1. Strict quality control of biopharmaceuticals to improve market growth

9.4 Cell Seperation

9.4.1. Growth in personalized medicine to improve market growth

9.5 Water Purification

9.5.1. Growth in aged population to improve market growth

9.6 Air Purification

9.6.1. Increased adoption of GMP practices to improve market growth

10.1 Introduction10.2 Manufacturing-Scale Operation

10.2.1. Expansion by pharmaceuticals to manufacture Covid-19 drugs to drive market growth

10.3 Pilot-Scale Operation

10.3.1. Increased outsourcing and cost-effective nature to promote market growth

10.4 R&D-Scale of Operation

10.4.1. Expenditure for R&D of Biologics to increase market growth

11.1. North America

11.1.1. United States11.1.2. Canada11.1.3. Mexico

11.2. Europe

11.2.1. Germany11.2.2. United Kingdom11.2.3. France11.2.4. Italy11.2.5. Spain11.2.6. Rest of Europe

11.3. Asia-Pacific

11.3.1. China11.3.2. Japan11.3.3. India11.3.4. Australia11.3.5. South Korea11.3.6. Rest of Asia-Pacific

11.4. South America

11.4.1. Brazil11.4.2. Argentina11.4.3. Rest of South America

11.5. Middle East & Africa

11.5.1. Kingdom of Saudi Arabia11.5.2. United Arab Emirates11.5.3. Rest of Middle East & Africa

12.1. Alfa Laval Corporate AB

12.1.1. Company details12.1.2. Financial outlook12.1.3. Product summary12.1.4. Recent developments

12.2. Amazon Filters LTD.

12.2.1. Company details12.2.2. Financial outlook12.2.3. Product summary12.2.4. Recent developments

12.3. Cantel Medical Corp.

12.3.1. Company details12.3.2. Financial outlook12.3.3. Product summary12.3.4. Recent developments

12.4. Cole-Parmer Instrument Company LCC.

12.4.1. Company details12.4.2. Financial outlook12.4.3. Product summary12.4.4. Recent developments

12.5. Corning Incorporated.

12.5.1. Company details12.5.2. Financial outlook12.5.3. Product summary12.5.4. Recent developments

12.6. Donaldson Company, Inc.

12.6.1. Company details12.6.2. Financial outlook12.6.3. Product summary12.6.4. Recent developments

12.7. Danaher Corporation

12.7.1. Company details12.7.2. Financial outlook12.7.3. Product summary12.7.4. Recent developments

12.8. Eaton Corporation PLC.

12.8.1. Company details12.8.2. Financial outlook12.8.3. Product summary12.8.4. Recent developments

12.9. Ertelalsop

12.9.1. Company details12.9.2. Financial outlook12.9.3. Product summary12.9.4. Recent developments

12.10. Filtrox AG.

12.10.1. Company details12.10.2. Financial outlook12.10.3. Product summary12.10.4. Recent developments

12.11. Freudenberg Filtration Technologies SE & CO.KG

12.11.1. Company details12.11.2. Financial outlook12.11.3. Product summary12.11.4. Recent developments

12.12. Graver Technologies, LLC.

12.12.1. Company details12.12.2. Financial outlook12.12.3. Product summary12.12.4. Recent developments

12.13. Kasag Swiss AG.

12.13.1. Company details12.13.2. Financial outlook12.13.3. Product summary12.13.4. Recent developments

12.14. Membrane Solutions.

12.14.1. Company details12.14.2. Financial outlook12.14.3. Product summary12.14.4. Recent developments

12.15. Merck KGAA.

12.15.1. Company details12.15.2. Financial outlook12.15.3. Product summary12.15.4. Recent developments

12.16. MMS AG

12.16.1. Company details12.16.2. Financial outlook12.16.3. Product summary12.16.4. Recent developments

12.17. Mann + Hummel International GMBH & CO. KG

12.17.1. Company details12.17.2. Financial outlook12.17.3. Product summary12.17.4. Recent developments

12.18. Meissner Filtration Products, INC.

12.18.1. Company details12.18.2. Financial outlook12.18.3. Product summary12.18.4. Recent developments

12.19. Parker + Hannifin Corporation.

12.19.1. Company details12.19.2. Financial outlook12.19.3. Product summary12.19.4. Recent developments

12.20. Porvair PLC.

12.20.1. Company details12.20.2. Financial outlook12.20.3. Product summary12.20.4. Recent developments

12.21. Repligen Corporation.

12.21.1. Company details12.21.2. Financial outlook12.21.3. Product summary12.21.4. Recent developments

12.22. Saint-Gobain Performance Plastics.

12.22.1. Company details12.22.2. Financial outlook12.22.3. Product summary12.22.4. Recent developments

12.23. Sartorius AG.

12.23.1. Company details12.23.2. Financial outlook12.23.3. Product summary12.23.4. Recent developments

12.24. 3M Company.

12.24.1. Company details12.24.2. Financial outlook12.24.3. Product summary12.24.4. Recent developments

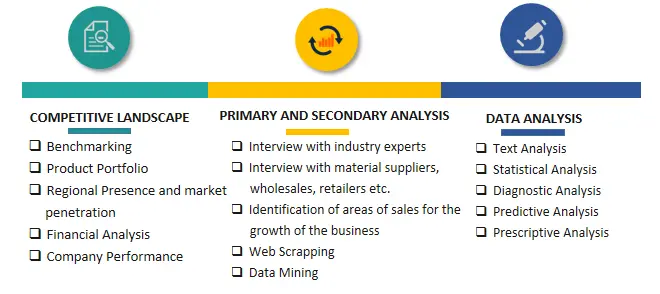

SPER Market Research’s methodology uses great emphasis on primary research to ensure that the market intelligence insights are up to date, reliable and accurate. Primary interviews are done with players involved in each phase of a supply chain to analyze the market forecasting. The secondary research method is used to help you fully understand how the future markets and the spending patterns look likes.

The report is based on in-depth qualitative and quantitative analysis of the Product Market. The quantitative analysis involves the application of various projection and sampling techniques. The qualitative analysis involves primary interviews, surveys, and vendor briefings. The data gathered as a result of these processes are validated through experts opinion. Our research methodology entails an ideal mixture of primary and secondary initiatives.

Frequently Asked Questions About This Report

PLACE AN ORDER

Year End Discount

Sample Report

Pre-Purchase Inquiry

NEED CUSTOMIZATION?

Request CustomizationCALL OR EMAIL US

100% Secure Payment

Related Reports

Our Global Clients

Our data-driven insights have influenced the strategy of 200+ reputed companies across the globe.